Glasses Manufacturing Process Introduction: Every Pair of Glasses Tells a Story

Each pair of glasses is not just a tool for blocking sunlight or correcting vision; they carry the creativity of designers and the story of the brand. Imagine a designer walking down the street, suddenly inspired by a splash of color, a unique shape, or a snippet of conversation. This spark of inspiration ultimately transforms into a distinctive pair of glasses through the intricate glasses manufacturing process, allowing people to express themselves in their daily lives.

Understanding the glasses manufacturing process helps brands establish a deeper emotional connection with consumers. Behind every stage is a culmination of effort, where consumers are not just purchasing a product, but also a story and a concept.

1. Inspiration Strikes: The Starting Point of Design

The design journey begins with a burst of inspiration. Our design team often seeks inspiration from everyday life, nature, art, and culture. For example, the curve of a fallen leaf might spark the creation of a new frame design, while the color palette of a street mural could inspire a series of sunglasses.

In addition to inspiration, we utilize AutoCAD to create detailed engineering drawings that define the precise dimensions of the glasses and each component. These CAD drawings serve as the foundation for the production of eyewear, ensuring accuracy in every detail.

On top of the engineering drawings, we produce color rendering visuals that showcase the designed colors applied to each style. This allows us to visualize the final product and make any necessary adjustments before production begins.

We also incorporate 3D design into our process. This method allows for a more immersive representation of the product, giving a clearer understanding of how the glasses will look and feel. However, 3D design is more time-consuming and incurs higher costs. Therefore, we typically rely on 2D drawings for production confirmation to save time and design costs.

Moreover, user research plays a crucial role in this process. By interacting with consumers, we gather feedback to understand their needs and preferences. Such research not only helps designers create glasses that truly meet market demands but also ensures that each product resonates with the consumer, making them feel the warmth and emotion behind the design.

In summary, the design process of eyewear is a journey that combines inspiration and need. Each pair of glasses has a story waiting to be shared with consumers, all while emphasizing the professionalism and creativity that Joysee Eyewear brings to the table.

2. Material Selection: A Fusion of Nature and Technology

In the glasses manufacturing process, material selection is crucial. Different materials, such as plastic, metal, wood, and recycled materials, significantly influence the appearance and functionality of eyewear, as well as their environmental impact. For example, plastic glasses are lightweight and colorful but can pose environmental challenges during production and disposal. Metal eyewear, on the other hand, is renowned for its durability and premium feel, catering to consumers who prioritize quality.

At Joysee Eyewear, we understand the importance of environmental responsibility, which drives our innovative material choices. We actively explore recyclable and bio-based materials to reduce the consumption of natural resources. Every detail is infused with meaningful thought about sustainability, allowing our products to not only be aesthetically pleasing but also to embody a sense of responsibility during production. We believe that high-quality eyewear should reflect a brand’s commitment to sustainable development, fostering emotional connections with consumers during their choices.

3. Production Process: Turning Creativity into Reality

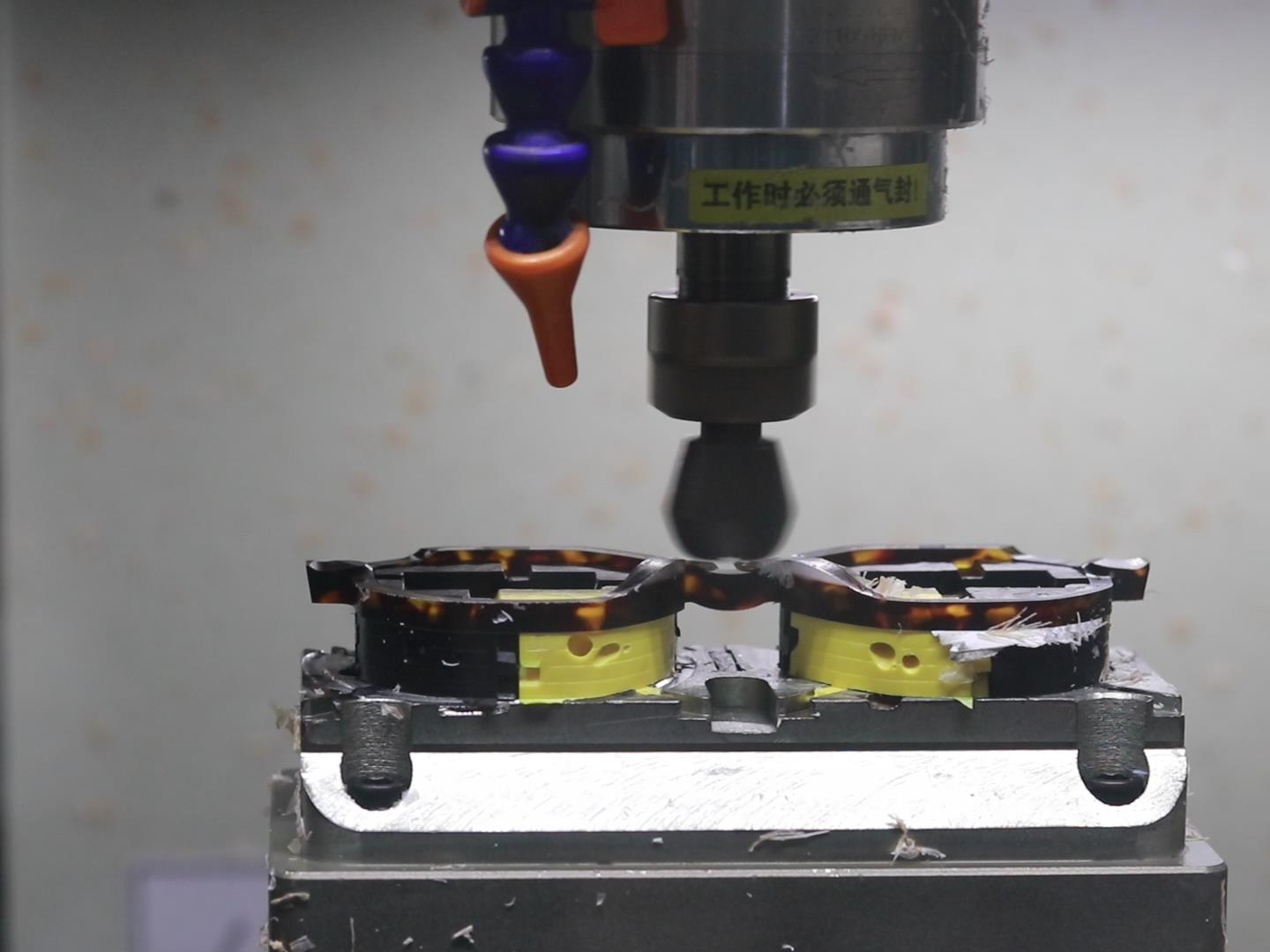

Transforming design sketches into tangible products is a fascinating process that involves cutting, shaping, polishing, and assembling various components. In this journey, we employ advanced technologies, such as 3D printing, laser cutting, and injection molding, which not only enhance production efficiency but also provide greater design flexibility.

Every step must be executed with precision; cutting materials is done according to exact dimensions specified in the design plans, ensuring each component fits perfectly. Shaping involves molding materials into ideal forms, while polishing adds a smooth finish and visual appeal. This seamless combination of techniques at Joysee Eyewear transforms creative ideas into reality, resulting in eyewear that embodies craftsmanship and innovation.

4. Assembly and Quality Control: A Commitment to Perfection

During the assembly phase, skilled artisans meticulously piece together each component, ensuring every pair of glasses meets high standards. Our artisans not only possess extensive experience but also share a deep passion for the products they create. In their hands, each pair of glasses becomes a work of art.

A rigorous quality control process runs throughout every stage of production. From raw material inspections to real-time monitoring during manufacturing and final product checks, we are dedicated to ensuring customer satisfaction. We recognize that consumers seek not just style in their eyewear, but also quality assurance. Joysee Eyewear is committed to ensuring that only rigorously tested products reach the market, delivering the best possible wearing experience to our customers.

By choosing Joysee Eyewear, you are selecting a glasses manufacturer that prioritizes sustainable practices, innovative design, and uncompromising quality.

5. Packaging and Delivery: Every Package is a Promise

Packaging is not just a means of protecting products; it also reflects the brand’s philosophy and the value of the product. At Joysee Eyewear, our packaging design aims to provide customers with a unique unboxing experience, conveying our care and attention for each customer. Every pair of glasses is meticulously packaged to ensure they are well-protected during transit, while also creating an engaging visual experience that excites customers.

In the delivery process, we pay attention to every detail. Choosing the right shipping methods and arranging reasonable timelines allows customers to feel anticipation during their wait. We promise that every order will arrive safely and on time, so that when customers open their packages, they can truly feel our dedication.

6. Market Feedback and Continuous Improvement: The Lifeblood of the Brand

After launching a product, collecting user feedback is crucial for the ongoing growth and development of the brand. By listening to our customers at Joysee Eyewear, we can identify strengths and weaknesses in our products, allowing us to make necessary improvements and optimizations. Customer reviews not only provide direct feedback but also reveal market trends, helping us stay ahead of industry dynamics.

By analyzing customer feedback and market trends, we can guide our next steps in design and production, ensuring our products continually meet consumer needs. This ongoing improvement process not only enhances product quality but also strengthens the brand’s vitality, enabling us to remain competitive in a challenging market.

Glasses Manufacturing Process Conclusion: The Infinite Possibilities Behind Eyewear

In conclusion, as we reflect on the entire process of glasses production, it becomes clear that choosing the right glasses manufacturer is vital for long-term brand success. Every detail, from design to delivery, impacts consumer experience and brand reputation. We encourage clients to connect with Joysee Eyewear to explore more about the stories and possibilities behind eyewear. Together, let’s create a future that is more innovative and environmentally conscious, moving forward hand in hand.

- Glasses Manufacturers—What to Look For in Your Partner

- 1. Innovative Customized Glasses Manufacturing Options

- 2. Glasses Manufacturers Quality Assurance: Standards, Testing

- 3. Benefits of Partnering with Chinese Glasses Manufacturers

- 4. Sustainable Eyewear Trends: Eco-Friendly Manufacturing Practices

- 5.Choosing Glasses Manufacturer for Your Brand

- 6. Glasses Manufacturing Process: How Eyewear is Made

- 7. Trends of Technology in Glasses Manufacturing

Allen Lin

Position: Owner

Company: Joysee Eyewear

Email: allen.lin@joysee-eyewear.com

WhatsApp: +8613456050627

Website: www.joysee-eyewear.com