La demande de lunettes de soleil ne cesse de croître dans le monde entier.fabricants d'unglass est cruciale pour le succès de votre marque. Que vous soyez une nouvelle marque émergente ou une entreprise établie, trouver un fabricant fiable peut vous aider à améliorer la qualité de vos produits et à accroître votre compétitivité sur le marché. Mais comment choisir le bon fabricant de lunettes de soleil ? Cet article répondra à des questions clés et vous aidera à prendre une décision éclairée.

Que faut-il rechercher chez les fabricants de lunettes de soleil ?

Qu'est-ce qui fait d'un fabricant de lunettes de soleil le bon choix pour votre marque ?

La clé de la sélection d'un bon fabricant de lunettes de soleil réside dans sa capacité à répondre à vos besoins en matière de produits et à offrir des services de personnalisation de haute qualité. Un bon fabricant doit disposer de l'expertise technique, de capacités de production stables et d'un système de contrôle de la qualité fiable.

Critères de sélection : Lors du choix d'un fabricant, les facteurs suivants sont essentiels :

- Qualité : Veiller à ce que les lunettes de soleil répondent aux normes de qualité internationales.

- Capacité de production : Le fabricant peut-il assurer une production à grande échelle ?

- Délai d'exécution : Le fabricant respecte-t-il le calendrier de livraison que vous vous êtes fixé ?

- Soutien à la clientèle : Le fabricant offre-t-il un excellent service après-vente et une assistance technique ?

Conseils pratiques :

- Visite d'usine : Si possible, visitez le site de production du fabricant pour vous rendre compte de ses capacités et de ses processus.

- Vérifier les références : Examinez les projets antérieurs du fabricant, en particulier son travail avec des industries ou des marques similaires.

Facteurs clés à prendre en compte lors du choix d'un fabricant de lunettes de soleil

| Critères | Détails | Approche de Joysee Eyewear |

|---|---|---|

| Expérience du fabricant | Les fabricants de lunettes de soleil ayant plus de 10 ans d'expérience sont plus à même de comprendre les tendances du marché et d'offrir des informations précieuses sur la production et la conception. | Joysee Eyewear a plus de 10 ans d'expérience, servant des clients internationaux avec des lunettes de haute qualité et recevant des commentaires positifs constants. |

| Qualité des produits et de l'artisanat | La qualité des matériaux et des processus de production a une incidence directe sur la réputation et la part de marché de la marque. | Nous effectuons des contrôles de produits depuis l'approvisionnement en matières premières jusqu'à chaque étape de la production, avec un contrôle de qualité final avant l'expédition. |

| Certifications et conformité | Les certifications internationales pertinentes telles que ISO, FDA et CE garantissent que les produits répondent aux normes mondiales de sécurité et de qualité. | Joysee Eyewear détient des certifications telles que CE, FDA, UKCA, BSCI et ISO, ce qui garantit que nos produits répondent aux normes internationales en matière de sécurité et de qualité. |

| Services de personnalisation | Offrir une gamme d'options de personnalisation, y compris les matériaux de la monture, le design, la fonctionnalité des verres et les couleurs, permet aux marques de se démarquer sur le marché. | Nous proposons des options de personnalisation étendues, notamment en ce qui concerne le choix des matériaux, la conception de la monture et les caractéristiques des verres, afin d'aider les marques à se différencier. |

1. Expérience du fabricant :

Un fabricant de lunettes de soleil expérimenté apporte une richesse de connaissances et d'expertise, qui peut s'avérer inestimable lorsqu'il s'agit de répondre à des demandes de personnalisation complexes et de suivre les tendances du marché en constante évolution. Les fabricants qui ont plus de dix ans d'expérience ont souvent mis en place des processus perfectionnés et une connaissance approfondie des demandes des consommateurs, ce qui leur permet d'offrir des conseils et d'innover comme ne peuvent le faire les fabricants moins expérimentés.

Par exemple, Joysee Eyewear, avec plus de 10 ans d'expérience, a servi des marques dans le monde entier, s'attirant des éloges constants pour sa capacité à fournir des produits de haute qualité et un service fiable. Cette vaste expérience nous permet d'anticiper les évolutions du marché et d'améliorer en permanence nos capacités de conception et de production, afin que vos produits restent à la pointe de la technologie.

2. Qualité du produit et de l'exécution :

La qualité de vos lunettes de soleil a un impact direct sur la réputation de votre marque et la fidélité de vos clients. Il est essentiel de choisir un fabricant qui utilise des matériaux de premier ordre et qui respecte des processus de contrôle de la qualité rigoureux tout au long de la production. Qu'il s'agisse de sélectionner des métaux et des plastiques de haute qualité pour les montures ou de s'assurer que les verres sont durables et offrent une protection optimale contre les UV, le bon fabricant veillera à ce que chaque aspect de vos lunettes de soleil réponde aux normes les plus strictes.

Chez Joysee Eyewear, nous sommes fiers de notre système complet de contrôle de la qualité. De l'approvisionnement en matières premières à chaque étape du processus de production, nous procédons à des inspections méticuleuses pour nous assurer que chaque produit est fabriqué à la perfection. Notre dernier contrôle de qualité est effectué juste avant l'expédition afin de garantir que chaque paire de lunettes de soleil répond aux attentes de nos clients et aux normes internationales.

3. Certifications et conformité :

Lorsque vous travaillez avec un fabricant de lunettes de soleil, il est essentiel de vous assurer qu'il possède les certifications nécessaires pour garantir que les produits répondent aux normes mondiales de sécurité et de qualité. Les certifications pertinentes, telles que ISO, FDA et CE, ne confirment pas seulement que le fabricant adhère aux normes de l'industrie, mais donnent également l'assurance que ses produits sont sûrs pour une utilisation par les consommateurs sur les différents marchés du monde.

Chez Joysee Eyewear, nous détenons plusieurs certifications essentielles, notamment CE, FDA, UKCA, BSCI et ISO, qui sont reconnues au niveau international. Cela signifie que nos produits sont conformes à des normes de sécurité et de qualité rigoureuses, ce qui permet de les distribuer dans la plupart des pays. Nos certifications assurent la tranquillité d'esprit de nos clients, qui savent que nous accordons la priorité à la conformité et à la sécurité.

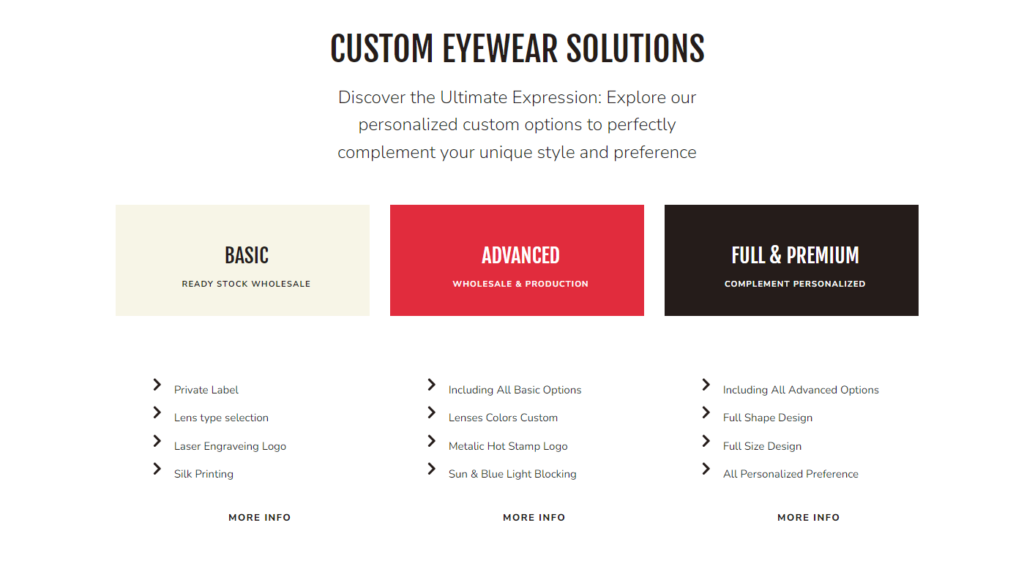

4. Services de personnalisation :

Pour aider votre marque à se démarquer sur le marché concurrentiel des lunettes, un grand fabricant de lunettes de soleil offrira un large éventail d'options de personnalisation. Celles-ci peuvent porter sur les matériaux de la monture, les caractéristiques du design, les fonctionnalités des verres et le choix des couleurs. Ces options de personnalisation vous permettent de répondre aux besoins uniques de votre public cible, qu'il s'agisse de modèles à la pointe de la mode, de matériaux respectueux de l'environnement ou de verres offrant des niveaux de protection UV spécifiques.

Chez Joysee Eyewear, nous proposons une gamme complète de services de personnalisation. De la sélection de matériaux et de montures de qualité supérieure à l'offre d'une grande variété de caractéristiques pour les verres, telles que le traitement antireflet, le blocage de la lumière bleue et les options polarisantes, nous offrons des possibilités infinies pour la conception de vos lunettes de soleil. Nous proposons également un large choix de couleurs et de finitions, afin que chaque modèle corresponde à l'identité de votre marque et plaise à vos clients.

Comment évaluer la qualité des lunettes de soleil des fabricants ?

| Critères d'évaluation | Détails | Approche de Joysee Eyewear |

|---|---|---|

| Processus de fabrication | Il s'agit de la conception de la monture, de la fabrication des verres et du revêtement de la surface. Les fabricants de lunettes de soleil de qualité supérieure utilisent des équipements et des technologies de pointe pour garantir la précision. | Nous utilisons des techniques avancées telles que la CNC, la gravure, le tumbling, le polissage et la galvanoplastie pour garantir la précision, la durabilité et la finition. |

| Contrôle de la qualité | Il s'agit d'inspections des matières premières, de contrôles d'échantillonnage en cours de processus et de tests sur le produit final afin de garantir des normes élevées à chaque étape de la production. | Nous effectuons des contrôles de qualité approfondis à chaque étape : matières premières, échantillonnage en cours de fabrication et inspections finales des produits avant leur expédition. |

| Commentaires des clients | Les témoignages de clients et les réussites reflètent la fiabilité et la qualité des produits d'un fabricant. Choisissez ceux qui ont fait leurs preuves. | Nous jouissons d'une solide réputation auprès des clients internationaux, qui nous font régulièrement part de leurs commentaires positifs et établissent des relations à long terme. |

T

1. Processus de fabrication :

Le processus de fabrication de lunettes de soleil de haute qualité comprend une série d'étapes précises, de la conception des montures à la fabrication des verres et à l'application de traitements de surface. Pour produire des lunettes de soleil durables et visuellement attrayantes, un fabricant doit utiliser des techniques et des équipements de pointe. Chaque étape du processus doit être méticuleusement exécutée pour garantir la précision, la durabilité et une finition impeccable.

Par exemple, les fabricants de haute qualité peuvent utiliser des techniques telles que l'usinage CNC (commande numérique par ordinateur) pour une découpe précise du cadre, la gravure pour créer des motifs complexes, le culbutage pour des bords de cadre lisses, le polissage pour une finition brillante et de qualité supérieure, et la galvanoplastie pour un revêtement de surface durable et agréable à l'œil. Ces procédés garantissent que le produit final répond à des normes élevées en matière d'artisanat, de durabilité et de design.

Chez Joysee Eyewear, nous utilisons ces méthodes de fabrication avancées pour nous assurer que chaque paire de lunettes de soleil que nous produisons est de la plus haute qualité, offrant à la fois style et résistance. Qu'il s'agisse de la CNC pour le façonnage complexe des montures ou de la galvanoplastie pour une finition durable et attrayante, nous employons les meilleures technologies du secteur.

2. Contrôle de la qualité :

Un solide processus de contrôle de la qualité est essentiel lors de l'évaluation d'un fabricant de lunettes de soleil. Garantir la qualité d'un produit ne se limite pas à une inspection finale : il s'agit de contrôler en permanence chaque étape du processus de fabrication. Un fabricant réputé dispose d'un système de contrôle de la qualité bien établi qui lui permet de détecter les éventuels défauts et de s'assurer que chaque produit répond aux normes les plus strictes.

Le processus de contrôle de la qualité comprend généralement

- Inspections des matières premières : Veiller à ce que tous les matériaux utilisés, tels que les matériaux des montures, les verres, les revêtements et les autres composants, soient de qualité supérieure et répondent aux normes spécifiées.

- Contrôles d'échantillonnage en cours de fabrication : Sélection aléatoire de lunettes de soleil au cours du processus de fabrication pour les tester. Il s'agit notamment de vérifier l'exactitude de la conception, de l'ajustement et de la cohérence des matériaux.

- Test du produit final : Avant d'expédier des lunettes de soleil, il convient de procéder à un contrôle final approfondi. Il s'agit notamment de tester la clarté optique, la protection contre les UV et la durabilité des verres. En outre, les montures sont inspectées pour vérifier le confort, l'ajustement et la solidité.

Chez Joysee Eyewear, nous mettons l'accent sur la qualité à chaque étape de la production. De l'inspection initiale des matières premières au contrôle continu tout au long du processus de fabrication, en passant par une dernière série de vérifications rigoureuses avant l'expédition, nous veillons à ce que chaque paire de lunettes de soleil réponde aux normes les plus strictes de l'industrie.

3. Commentaires des clients :

Les commentaires des clients sont l'un des moyens les plus fiables d'évaluer la qualité et la fiabilité d'un fabricant de lunettes de soleil. Lorsque vous évaluez un fabricant potentiel, recherchez les témoignages et les réussites des marques qui ont travaillé avec lui. Les commentaires positifs émanant d'entreprises de renom peuvent être un bon indicateur de la capacité du fabricant à fournir des produits de haute qualité et un excellent service à la clientèle.

Choisir un fabricant qui a fait ses preuves, en particulier avec des marques bien établies, peut vous donner confiance en sa capacité à répondre à vos besoins et à produire des lunettes de soleil qui répondent à vos attentes. En outre, pensez à demander au fabricant des études de cas ou des exemples de travaux antérieurs pour mieux comprendre le type de résultats qu'il a obtenus pour d'autres clients.

Au Lunettes JoyseeEn tant que fabricant de lunettes de soleil, nous nous sommes forgé une solide réputation auprès de nos clients du monde entier. Nous comptons parmi nos clients des marques internationales de renom, et nous avons reçu des éloges constants pour notre souci du détail, notre approche centrée sur le client et la qualité générale de nos lunettes de soleil. Nous encourageons nos clients potentiels à consulter nos exemples de réussite et les témoignages de nos clients pour comprendre comment nous avons toujours fourni des produits qui dépassent les attentes.

Comment personnaliser les lunettes de soleil avec votre fabricant ?

Les étapes de la personnalisation :

Le processus de personnalisation des lunettes de soleil comprend généralement plusieurs étapes clés :

:

| Étape | Description |

|---|---|

| 1. Phase de conception | - Collaborez avec votre fabricant pour définir les modèles de cadres, les couleurs et les caractéristiques fonctionnelles. |

| - Choisissez des matériaux tels que le métal, le plastique, le bois ou des options écologiques. | |

| - Sélectionnez les styles de monture (aviateur, wayfarer, rond) et les caractéristiques des verres (protection UV, blocage de la lumière bleue). | |

| 2. Production d'échantillons | - Le fabricant crée des échantillons sur la base des spécifications du projet. |

| - Des ajustements sont effectués après examen de l'échantillon afin d'affiner le produit. | |

| 3. Production de masse | - Une fois l'échantillon approuvé, la production en série commence. |

| - La production garantit une qualité constante et le respect des choix de personnalisation effectués lors des phases précédentes. |

Phase de conception :

- Conception du cadre: Collaborez étroitement avec votre fabricant pour définir le style et la forme des montures. Discutez des matériaux tels que le métal, l'acétate ou les matériaux écologiques comme le bambou ou le plastique recyclé. Les styles de montures peuvent être aviateur, wayfarer ou rond, et les modèles peuvent être adaptés pour répondre aux goûts spécifiques des consommateurs.

- Caractéristiques de l'objectif: Choisissez des verres qui répondent aux besoins de votre marché, y compris des options telles que les verres polarisants pour réduire l'éblouissement, le blocage de la lumière bleue pour la protection de l'écran, les verres photochromiques pour les transitions intérieur/extérieur, et les verres haute définition pour la clarté.

- Couleurs et finitions: Choisissez parmi une large gamme de couleurs, de motifs et de finitions pour les montures et les verres. Des options de couleurs personnalisées ou des finitions mates ou brillantes peuvent ajouter un aspect distinct à votre marque.

Production d'échantillons :

- Une fois que vous vous êtes mis d'accord sur le design et les spécifications, le fabricant crée un échantillon sur la base de ces détails. Cet échantillon est essentiel pour évaluer la coupe, le style et la fonctionnalité.

- La phase de production d'échantillons permet de procéder à des ajustements et à des mises au point. Les fabricants peuvent proposer plusieurs itérations, ce qui vous permet d'affiner le produit jusqu'à ce qu'il réponde à vos attentes. Vous pouvez également choisir d'inclure des caractéristiques personnalisées, telles que des gravures spéciales, des couleurs uniques ou des éléments de conception en édition limitée.

Production de masse :

- Après avoir finalisé l'échantillon et reçu l'approbation, le fabricant commencera la production en série de vos lunettes de soleil. Cette étape consiste à passer des prototypes à la production du volume requis pour votre marché.

- Les fabricants de lunettes de soleil veilleront à ce que la production respecte les normes de qualité, maintienne des caractéristiques de conception cohérentes et intègre les choix de personnalisation effectués au cours des phases précédentes.

Options de personnalisation :

| Option de personnalisation | Description |

|---|---|

| Conception du cadre | - Choisissez les matériaux : métal, plastique, acétate, bois ou options durables. |

| - Sélectionnez les styles de montures : surdimensionné, rétro, sportif, classique, moderne, etc. | |

| - Choisissez les couleurs : classiques (noir, marron), finitions métalliques, teintes vives ou motifs personnalisés. | |

| Caractéristiques de l'objectif | - Protection contre les UV : Protège les yeux des rayons UV nocifs. |

| - Blocage de la lumière bleue : Prévient la fatigue oculaire numérique. | |

| - Polarisation : Réduit l'éblouissement dû aux surfaces réfléchissantes (idéal pour l'extérieur et la conduite). | |

| - Verres dégradés : Protègent de la lumière du soleil tout en maintenant la visibilité. | |

| - Revêtement miroir : Réduit la quantité de lumière qui pénètre dans les yeux. | |

| - Photochromiques : Les verres s'adaptent aux changements de luminosité. | |

| L'image de marque | - Ajoutez des logos ou des gravures personnalisés sur les montures ou les verres. |

| - Personnaliser l'emballage : étuis, pochettes et boîtes de présentation de marque. | |

| Caractéristiques supplémentaires | - Caractéristiques de confort : Plaquettes de nez réglables, embouts de branches personnalisés et charnières pour un meilleur ajustement et un plus grand confort. |

| - Durabilité : Matériaux tels que le bambou, le plastique recyclé et les cadres biodégradables pour les marchés soucieux de l'environnement. |

Plusieurs options sont disponibles pour la personnalisation des lunettes de soleil :

Conception du cadre :

- Choisissez parmi des matériaux tels que métal, plastique, acétateou des alternatives durables telles que bois ou matériaux recyclés. Les différents matériaux offrent des propriétés uniques telles que la légèreté, la durabilité ou des options respectueuses de l'environnement.

- Le style du cadre peut aller du classique au moderne, en passant par des designs plus audacieux. Des options telles que surdimensionné, rétroou sportif répondent aux différentes préférences des clients.

- Les couleurs peuvent varier du noir classique, des bruns et des finitions métalliques aux teintes vives ou aux motifs personnalisés.

Caractéristiques de l'objectif :

- Protection UV: Indispensable pour protéger les yeux contre les rayons UV nocifs, ce qui garantit un produit de qualité qui protège également la santé de vos clients.

- Blocage de la lumière bleue: Idéal pour ceux qui passent de longues heures devant des écrans numériques, afin de prévenir la fatigue oculaire.

- Polarisation: Idéal pour l'extérieur et la conduite, il réduit l'éblouissement dû aux surfaces réfléchissantes telles que l'eau ou le verre.

- Lentilles dégradées: Verres qui s'assombrissent de haut en bas, offrant une meilleure protection contre les rayons du soleil tout en préservant la visibilité.

- Revêtement miroir: Ajoute une finition élégante et réduit la quantité de lumière qui atteint les yeux.

- Photochromique: Des lentilles qui s'adaptent aux conditions de luminosité changeantes, offrant un confort dans les environnements lumineux comme dans les environnements peu éclairés.

L'image de marque :

- L'ajout de logos ou de gravures personnalisés peut rendre vos lunettes de soleil encore plus uniques. Qu'il s'agisse d'un gravure au laser de votre marque sur le temple ou sur les logos estampillés sur les lentilles, l'image de marque permet d'établir une identité unique.

- Les fabricants de lunettes de soleil peuvent également proposer des options d'emballage personnalisées, telles que des étuis, des pochettes et des boîtes de présentation de marque pour améliorer la présentation de votre produit.

Caractéristiques supplémentaires :

- Options de confort: Personnalisez les plaquettes de nez, les embouts de branches et les charnières pour améliorer l'ajustement et le confort. Par exemple, des plaquettes de nez réglables peuvent être ajoutées pour assurer une meilleure adaptation aux différentes formes de visage.

- Durabilité: Si votre marché cible les consommateurs soucieux de l'environnement, travaillez avec des fabricants de lunettes de soleil qui proposent des matériaux durables tels que le bambou, les plastiques recyclés ou les montures biodégradables.

Personnalisation en fonction des besoins du marché :

| Considérations sur le marché | Description |

|---|---|

| Des marchés à la pointe de la mode | - L'accent est mis sur des modèles esthétiques et à la mode, avec des combinaisons de couleurs uniques et des éditions exclusives. |

| - Matériaux haut de gamme (par exemple, titane, finitions en or) et emballage de luxe. | |

| Marchés des lunettes fonctionnelles | - L'accent est mis sur la durabilité, le confort et la performance des verres (par exemple, des branches antidérapantes, des modèles légers, des verres de haute performance). |

| Consommateurs soucieux de l'environnement | - Utilisez des matériaux durables tels que les plastiques recyclés, le bambou et le bois pour attirer les acheteurs soucieux de l'environnement. |

Lorsque vous personnalisez des lunettes de soleil, il est essentiel de tenir compte des préférences et des besoins de votre marché cible. Adaptez vos choix en matière de design en fonction des éléments suivants :

Des marchés à la pointe de la mode:

- Pour les consommateurs soucieux de la mode, l'accent est mis sur la conception, styleet esthétique l'attrait des lunettes de soleil. Ce marché peut donner la priorité à la tendance des cadres, les combinaisons de couleurset Modèles en édition limitée qui font appel à leur sens du style et de l'exclusivité.

- Les marchés de la haute couture ou du luxe peuvent également rechercher matériaux de qualité supérieure tels que titane, l'orou finitions platine, associé à emballage de luxe.

Marchés des lunettes fonctionnelles:

- Pour les consommateurs intéressés par des lunettes fonctionnelles, les priorités sont les suivantes technologie des lentilles et caractéristiques de confort. Les marchés tels que le sport, les activités de plein air ou les lunettes de prescription peuvent se concentrer davantage sur la durabilité, le confort et les performances des verres plutôt que sur l'esthétique.

- Vous pouvez vous concentrer sur antidérapant pour les lunettes de soleil de sport, conceptions légères pour une utilisation tout au long de la journée, ou lentilles de haute performance qui offrent une clarté et une protection supérieures dans des conditions extrêmes.

Consommateurs soucieux de l'environnement:

- Si vous ciblez les marchés soucieux de l'environnement, vous pouvez opter pour les produits suivants durable et matériaux respectueux de l'environnement. En utilisant plastiques recyclés, matériaux biodégradablesou ressources naturelles comme bambou et bois peuvent attirer les acheteurs soucieux de l'environnement.

Comment s'assurer de la fiabilité des livraisons et de la qualité des fabricants de lunettes de soleil ?

Délai d'exécution :

Le délai de production des lunettes de soleil dépend en grande partie de la complexité des personnalisations et du volume de la commande. Il est essentiel de communiquer clairement votre délai de livraison au fabricant dès le départ afin d'éviter les surprises ultérieures. Un fabricant transparent sur ses délais de livraison vous permettra de planifier en conséquence et de gérer efficacement les attentes des clients. Assurez-vous que le fabricant est en mesure de traiter aussi bien les petites que les grandes commandes dans des délais cohérents. Les délais d'exécution standard pour les lunettes de soleil personnalisées peuvent varier de 4 à 8 semaines, en fonction de facteurs tels que la disponibilité des matériaux et la capacité de production. Il est également important de tenir compte des délais d'expédition pour s'assurer que les produits arrivent à temps.

Gestion de la chaîne d'approvisionnement :

Une chaîne d'approvisionnement bien structurée est essentielle pour garantir que les lunettes de soleil sont produites efficacement et livrées à temps. Les fabricants de lunettes de soleil doivent mettre en place des plans d'urgence en cas de perturbations inattendues, telles que des pénuries de matières premières, des retards de transport ou des pénuries de main-d'œuvre. Cela permet d'éviter les retards de production et de s'assurer que les commandes sont honorées comme prévu. Un système fiable de gestion de la chaîne d'approvisionnement comprend également des relations étroites avec les principaux fournisseurs et prestataires logistiques, ce qui permet au fabricant de maintenir les niveaux de stock et de gérer efficacement les calendriers de production. En vous associant à un fabricant qui dispose d'une chaîne d'approvisionnement solide, vous éviterez les risques de retards et de complications de dernière minute.

Résolution des problèmes :

Dans tout processus de fabrication, des problèmes peuvent survenir et avoir une incidence sur les délais de livraison ou la qualité des produits. Il est essentiel de choisir un fabricant qui a fait ses preuves en matière de résolution rapide et efficace des problèmes. Qu'il s'agisse d'un retard de production ou d'un problème de qualité du produit final, le fabricant doit disposer d'une procédure établie pour résoudre ces problèmes. Recherchez des fabricants de lunettes de soleil qui offrent un solide service après-vente et qui communiquent clairement tout au long du processus de résolution des problèmes. Une résolution efficace des problèmes permet non seulement de minimiser les perturbations, mais aussi d'instaurer un climat de confiance entre vous et le fabricant, gage d'une coopération à long terme.

Certifications des fabricants de lunettes de soleil : Que faut-il vérifier ?

Certification ISO :

La certification ISO est l'une des normes de système de gestion de la qualité les plus reconnues au monde. Les fabricants certifiés ISO ont satisfait à des critères stricts en matière de qualité et de cohérence des produits. Cette certification garantit que le fabricant adhère aux meilleures pratiques en matière de contrôle de la qualité, de gestion de la production et de processus d'amélioration continue. Lors de la sélection d'un fabricant de lunettes de soleil, il est essentiel de choisir un fabricant certifié ISO pour s'assurer que ses produits répondent aux normes internationales en matière de sécurité, de performance et de fiabilité. Cette certification peut également contribuer à rationaliser les processus d'exportation, car de nombreux pays exigent des produits conformes à la norme ISO pour entrer sur leur territoire.

Autres certifications :

Outre la certification ISO, d'autres certifications importantes peuvent valider l'engagement du fabricant en faveur de la qualité et de la sécurité des produits. L'approbation de la FDA, par exemple, garantit que les lunettes de soleil sont conformes aux règles de santé et de sécurité établies par le gouvernement américain. Le marquage CE, quant à lui, est exigé pour les produits vendus dans l'Espace économique européen (EEE) et signifie que le produit est conforme aux normes européennes en matière de santé, de sécurité et d'environnement. Les fabricants qui détiennent ces certifications peuvent vous aider à vous assurer que vos lunettes de soleil répondent aux exigences réglementaires nécessaires pour les marchés internationaux. Vérifiez toujours les certifications d'un fabricant avant de passer commande.

Les erreurs à éviter lors du choix d'un fabricant de lunettes de soleil

Ignorer les certifications de qualité :

L'une des erreurs les plus courantes que commettent les entreprises lorsqu'elles choisissent un fabricant de lunettes de soleil est de négliger l'importance des certifications de qualité. En l'absence de certifications telles que ISO, FDA ou CE, les lunettes de soleil risquent de ne pas répondre aux normes de qualité requises, ce qui pourrait nuire à la réputation de votre marque. Le fait de ne pas vérifier ces certifications peut entraîner des produits défectueux, des matériaux dangereux ou le non-respect des réglementations internationales, ce qui peut conduire à des rappels coûteux ou à des problèmes juridiques. Assurez-vous toujours que le fabricant est certifié pour répondre aux normes nécessaires pour votre marché cible.

Se concentrer uniquement sur le prix :

Si le prix est incontestablement un facteur important, le fait de choisir un fabricant uniquement sur la base du prix le plus bas peut conduire à compromettre la qualité. Il est essentiel de trouver un équilibre entre le prix, la qualité du produit et la valeur. Un fabricant moins cher peut faire des économies en utilisant des matériaux de qualité inférieure, en offrant des options de personnalisation limitées ou en n'appliquant pas de processus de contrôle de la qualité. En revanche, investir dans un fabricant qui propose des lunettes de soleil de qualité supérieure peut se traduire par une plus grande satisfaction de la clientèle, une fidélisation des clients et une amélioration de l'image de marque. Considérez les avantages à long terme du choix d'un fabricant qui fournit des produits de haute qualité et des services fiables, car cela contribuera au succès de votre marque au fil du temps.

Négliger les besoins de personnalisation :

La personnalisation est un élément clé de différenciation dans le secteur de la lunetterie. Si vous négligez l'importance de la personnalisation lors de la sélection d'un fabricant, vos lunettes de soleil risquent de ne pas avoir les qualités uniques qui permettent à votre marque de se démarquer sur le marché. La personnalisation vous permet d'adapter les matériaux de la monture, les caractéristiques des verres et la marque aux besoins spécifiques de vos clients cibles. En proposant des designs, des couleurs et des fonctionnalités personnalisés, vous pouvez créer des lunettes de soleil qui reflètent l'identité de votre marque et attirent votre public cible. Un fabricant disposant de solides capacités de personnalisation peut vous aider à créer des produits qui trouvent un écho auprès de vos clients et vous donnent un avantage concurrentiel sur le marché.

Conclusion : Faire le meilleur choix pour vos fabricants de lunettes de soleil

Choisir le bon fabricants de lunettes de soleil est une décision cruciale qui peut avoir un impact significatif sur le succès de votre marque. En tenant compte de facteurs tels que l'expérience, les certifications de qualité, les capacités de personnalisation, la fiabilité de la chaîne d'approvisionnement et la résolution des problèmes, vous pouvez prendre une décision éclairée qui s'aligne sur vos objectifs commerciaux. Donnez toujours la priorité à la qualité, car elle a une incidence directe sur la satisfaction des clients et la réputation de la marque. Un fabricant digne de confiance offrira non seulement des produits de haute qualité, mais aussi une assistance solide et des capacités de résolution des problèmes pour aider votre marque à se développer. Un partenariat avec un fabricant fiable et certifié vous mettra sur la voie d'une réussite à long terme dans le secteur de la lunetterie.