1. Introduction

In today’s rapidly evolving technological landscape, advanced technology plays a crucial role in the Blue Light Blocking Glasses Manufacturer. These technological advancements not only enhance product performance but also drive growth in the entire industry.

Importance of Blue Light Blocking

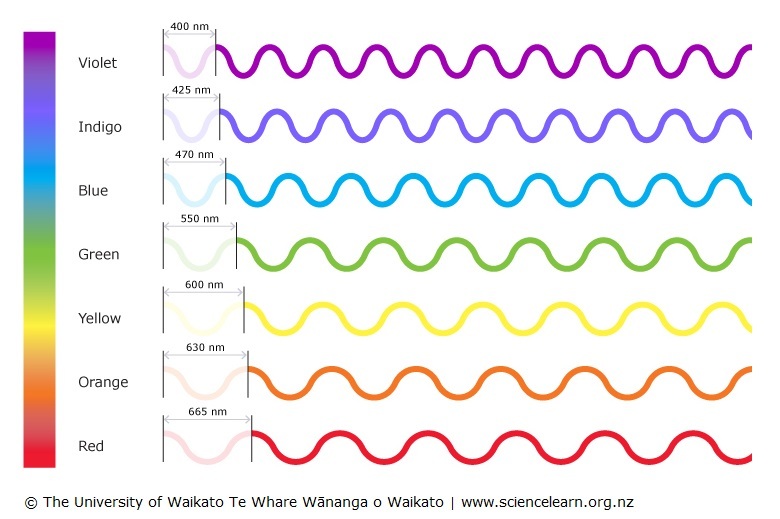

With the proliferation of digital devices, increasing attention is being paid to blue light exposure. Blue light is believed to negatively impact eye health, leading to issues such as digital eye strain, dry eyes, and sleep disturbances. Research indicates that blue light exposure, especially during evening hours, can disrupt circadian rhythms, affecting sleep quality. Thus, using blue light blocking glasses has become an effective solution. Advanced materials and manufacturing processes can significantly enhance the blue light blocking effectiveness of lenses, providing better protection for users.

2. Advantages of Our Blue Light Blocking Glasses Manufacturer Technology

Advanced Equipment

As a leading blue light blocking glasses manufacturer, we have a deep understanding of blue light lenses. Different materials can present certain limitations when paired with frames. For example, some high-index lenses may have edge thickness limitations that need to be considered based on the frame design.

We emphasize the blue light blocking capabilities of our lenses, which are closely linked to the choice of base materials and coating technologies. Studies show that lenses with specific coatings can block up to 99% of harmful blue light, depending on the material used.

Specific Equipment Details

We utilize advanced materials like high-index plastic and polycarbonate, which offer excellent optical performance and lightweight benefits while effectively blocking blue light. Additionally, dyeing and coating technologies significantly enhance the blue light blocking effect and durability of the lenses. For instance, anti-reflective coating (AR Coating) can reduce glare by up to 50%, improving visual comfort, especially during prolonged use of electronic devices.

To ensure high efficiency and precision, we employ automated lens cutting machines and coating equipment. These advanced machines help us optimize our production processes and maintain quality.

3. Ensuring Blue Light Blocking Effectiveness

Proceso de fabricación

Ensuring the blue light blocking effectiveness of our glasses is a comprehensive process. Different usage scenarios, such as computer work, smartphone use, and outdoor activities, require specific types of blue light blocking glasses. Each scenario demands particular lens colors and blocking capabilities. For example, yellow-tinted lenses are suitable for indoor use, filtering out certain blue light wavelengths, while gray lenses are ideal for outdoor conditions, effectively reducing overall light intensity.

Moreover, we implement strict quality control measures for every batch of products to ensure they meet industry standards, providing customers with the highest quality blue light blocking glasses.

Materials Used

The types of lenses we use include:

- Optical glass

- High-index plastic

- Polycarbonate

Material Details

When selecting materials, we focus on their ability to enhance blue light blocking effects. For example, blue light blocking coatings can significantly improve lens performance. Studies indicate that lenses with these coatings can block over 40% of blue light, enhancing visual comfort and reducing the risk of eye strain. We also consider the scratch resistance and impact resistance of materials to ensure that our products meet safety standards and can withstand various environments.

Through these advanced technologies and materials, we are committed to providing high-quality blue light blocking glasses that meet the diverse needs of our customers.

4. Quality Assurance and Certification

Quality Control System in Blue Light Blocking Glasses Manufacturer

As a leading blue light blocking glasses manufacturer, maintaining high-quality production is essential. We adhere to strict quality control standards to ensure that every product meets rigorous quality requirements. Our quality control process includes several key steps:

High Standard Production Processes:

We conduct stringent testing on raw materials upon arrival to ensure they meet our quality criteria. Throughout the production process, real-time monitoring technologies are utilized to inspect each stage, and final products undergo comprehensive testing to ensure performance and safety.

International Certifications: We have obtained multiple international quality certifications, such as ISO 9001 and CE certification. These certifications not only validate that our production processes meet global industry standards but also enhance customer trust in our products. This positions us favorably in a competitive market.

Continuous Improvement: We are committed to continuous improvement, utilizing customer feedback and regular reviews to enhance product quality. Furthermore, we provide ongoing training for our staff to ensure that the team is well-versed in the latest quality management practices and technologies.

5. Achieving Cost-Effectiveness Without Compromising Quality

Production Efficiency

At our company, we strive to achieve cost-effectiveness without compromising the quality of our blue light blocking glasses. By integrating advanced automation technologies and modern manufacturing processes, we significantly enhance production efficiency, reducing human error and production time. For instance, investments in cutting-edge machinery have streamlined our production lines, leading to lower overall production costs.

Cost Savings from Advanced Technologies: These technological improvements enable us to lower production costs, allowing us to pass those savings on to our customers. Research indicates that manufacturers utilizing advanced technology can reduce operational costs by up to 30%, allowing us to offer high-quality blue light blocking glasses at competitive prices.

Passing Savings to Customers: Our pricing strategy thus becomes more competitive, attracting more customers to choose our products. Our goal is to provide customers with the best balance of quality and value.

6. Customization Services

Tailored Solutions for Customers

As a prominent blue light blocking glasses manufacturer, we possess strong customization capabilities to meet the specific needs of our customers. Our manufacturing processes allow us to provide tailored solutions for blue light blocking glasses.

Personalized Production Capabilities: We can customize lens colors, frame designs, and special coatings based on customer requirements. Whether for individual users or corporate clients, we offer products that align with their brand image and market needs.

Case Studies: For instance, we developed a customized series of blue light blocking glasses for a fashion brand to diversify their product line. Through our customization services, the client not only enhanced their brand image but also improved their market competitiveness. These successful cases demonstrate our flexibility and responsiveness in providing customized services.

7. Conclusion

In summarizing the advantages of our blue light blocking glasses manufacturing, we emphasize the importance of advanced technology in the production process. Our focus on quality control, cost-effectiveness, and customization services not only enhances product quality but also offers customers a wider range of choices.

We invite potential customers to contact us for more information about our customized solutions or to schedule a consultation to explore collaboration opportunities. We look forward to working together to create a brighter future!

Explore the Expertise of Blue Light Glasses Manufacturers

Why Partner with a Professional Blue Light Blocking Glasses Manufacturer?

Discover why partnering with a professional manufacturer is crucial for the quality and performance of blue light glasses.How Blue Cut Lenses Company Strengthened Brands with Blue Light Glasses Solutions

Learn how blue light glasses solutions can boost brand competitiveness in the market.Blue Light Glasses Manufacturer and Trends

Explore current trends and market demands in the blue light glasses industry, providing insights for future growth.Certificaciones para proveedores de gafas de protección contra la luz azul

Understand the importance of supplier certifications and their impact on product quality.Customization Solutions at Blue Light Glasses Supplier for Market Differentiation

Discover how custom services from blue light glasses suppliers can help brands stand out in the market.Blue Light Blocking Glasses Manufacturer: Advanced Technology Overview

An overview of advanced technology used in blue light glasses manufacturing, ensuring high-quality products for clients.

Allen Lin

Cargo: Propietario

Empresa: Joysee Gafas

Correo electrónico: allen.lin@joysee-eyewear.com

WhatsApp: +8613456050627

Página web: www.joysee-eyewear.com