Customized Glasses Manufacturing Introduction

Customization has become a pivotal element in the eyewear industry, driving manufacturers to cater to the unique preferences of consumers. With the increasing demand for personalized products, glasses manufacturers are focusing on customization services that not only enhance the aesthetic appeal of eyewear but also improve functionality. This article will delve into the various options available in customized glasses manufacturing, including material choices, lens features, and design possibilities, illustrating how these elements can set a brand apart in a competitive market.

1. Customized Glasses Manufacturing Material Choices

In customized glasses manufacturing, the choice of materials is crucial. Different materials not only impact the aesthetics and comfort of eyewear but also influence functionality and durability. At Joysee Eyewear, we prioritize quality materials to ensure our products meet diverse consumer needs. Below are some of the main material options available for customized glasses.

Metal Materials

- Copper: Known for its excellent malleability and corrosion resistance, copper is an ideal choice for lightweight frames. Its classic appeal makes it a popular option in customized glasses manufacturing, allowing for intricate designs.

- Stainless Steel: This high-strength material is resistant to wear and tear, making it perfect for everyday eyewear. Stainless steel frames can be treated with various finishes, adding a modern touch to customized eyewear designs.

- Aluminum-Magnesium Alloy: Combining lightness and strength, this material is often used for sporty and trendy styles. Its lightweight nature enhances comfort, making it a favored choice in glasses manufacturers’ customization options.

- Titanium Alloy: Renowned for its lightweight and high corrosion resistance, titanium is the go-to material for high-end eyewear. It offers exceptional durability, making it ideal for long-lasting customized glasses.

Injection-Molded Plastics

- Polycarbonate: This lightweight and impact-resistant plastic is perfect for children’s eyewear and sports glasses. Its superior safety features make it a popular choice among parents and active individuals, fitting well into the glasses customization services offered by manufacturers.

- TR90: This flexible and durable material is exceptionally comfortable, making it suitable for a wide range of customized designs. TR90 frames can withstand high temperatures and are resistant to stress, ensuring long-lasting wear.

- Acrylic Plastics: Commonly used in high-end eyewear, acrylic provides various color and design options, allowing brands to express creativity in their customized glasses manufacturing.

Sheet Plastics

- Acetate: This material is favored for its elegant appearance and vibrant color options. Acetate frames can be designed in various styles, making them a staple in the customization offerings of glasses manufacturers.

- Bio Acetate: An eco-friendly alternative, bio acetate provides comfort and durability. It caters to the growing demand for sustainable products in the eyewear market, aligning with the customization services that meet consumer preferences.

Bamboo and Wood Materials

- Bamboo: This natural material is not only lightweight but also environmentally friendly, making it increasingly popular in fashionable eyewear. Bamboo frames offer a unique style that can appeal to eco-conscious consumers seeking customized options.

- Wood: With its distinctive grain patterns and appearance, wooden eyewear stands out as a trendy choice. Customizing wooden frames can add a personal touch, aligning with the desires of today’s consumers for unique and stylish glasses.

By carefully selecting these materials, eyewear manufacturers like Joysee Eyewear can provide personalized customization services that meet the growing demand for unique designs and functionality. Brands must consider their target market and consumer preferences when choosing materials, enhancing the competitiveness of their customized glasses manufacturing offerings.

2. Customized glasses manufacturing Design Choices

In customized glasses manufacturing, design choices play a pivotal role in enhancing brand identity and meeting consumer preferences. At Joysee Eyewear, we understand the importance of offering a diverse range of design options that allow brands to stand out in the competitive eyewear market. Below are some key aspects of our design choices.

Material Colors and Designs

Diverse Color Options: We offer a wide array of color choices, including classic hues, trendy shades, and fully customized colors tailored to your brand’s identity. By leveraging color psychology, we help brands enhance their personality and appeal to target audiences. Whether you’re looking for timeless black frames or vibrant, eye-catching colors, our customized glasses manufacturing ensures that your eyewear reflects your unique style.

Design Styles: Our design capabilities include various styles such as modern, vintage, and minimalist designs. Each style can be tailored to match different brand images, allowing companies to effectively communicate their values through eyewear. Whether you prefer sleek contemporary frames or charming retro designs, Joysee Eyewear provides customization services that cater to your brand’s aesthetic.

Custom Logo and Placement

Printing Techniques: At Joysee Eyewear, we utilize advanced printing technologies, including screen printing and laser engraving, to imprint your brand logo onto the eyewear. These techniques offer high durability and precision, ensuring your logo maintains its integrity over time. The choice of printing method enhances the quality of the finished product, making it an essential aspect of our customized glasses manufacturing process.

Location Selection: We provide various options for logo placement on the frames, such as on the temples, lenses, or bridge. Each location impacts brand exposure differently, allowing you to choose the most effective way to showcase your logo. For instance, placing your logo on the temple ensures visibility while worn, enhancing brand recognition.

Design Formats and Proposals Customized Glasses Manufacturing

Client Involvement: We believe in collaborating closely with our clients throughout the design process. By inviting customers to participate, whether through online design tools or preliminary sketches, we gather valuable feedback that informs the final product. This collaborative approach not only empowers brands but also aligns our customized glasses manufacturing with their specific needs.

Sample Presentation: To aid in the decision-making process, we offer sample displays of the eyewear. Clients can preview the actual look and feel of the products before finalizing their choices. This step is crucial in ensuring that the final product meets expectations, reinforcing the quality and customization options available through Joysee Eyewear.

By incorporating these design choices into our customized glasses manufacturing, Joysee Eyewear helps brands effectively express their identity while ensuring functionality and style. Our commitment to quality and innovation makes us a preferred partner for companies looking to enhance their eyewear offerings.

Customized Glasses Manufacturing Conclusion

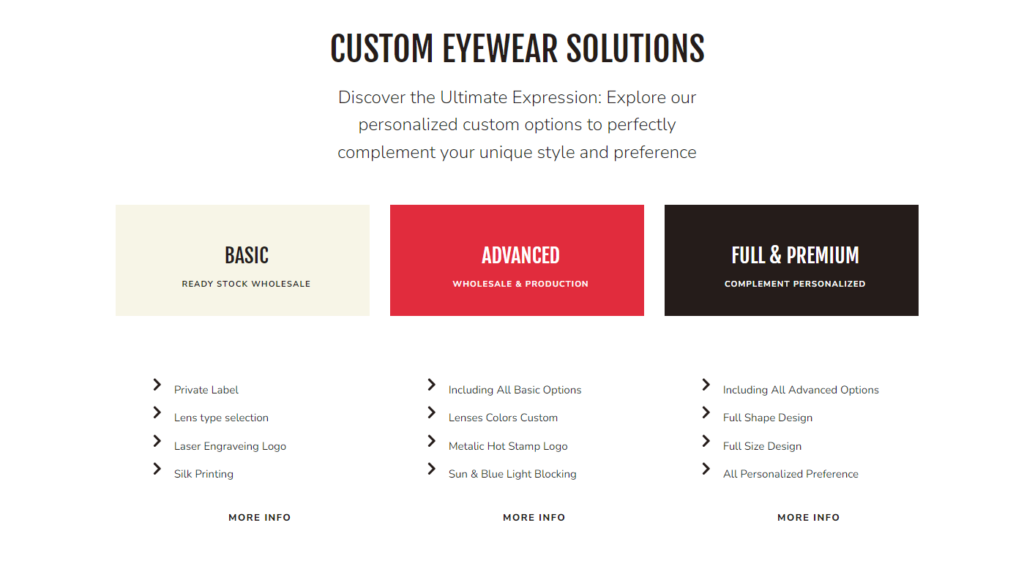

In conclusion, choosing customized glasses is not just a trend; it’s a strategic decision that empowers brands to differentiate themselves in the competitive eyewear market. The advantages of customized glasses manufacturing extend beyond aesthetics. By leveraging our extensive customization services at Joysee Eyewear, brands can enhance their identity, improve customer loyalty, and ultimately boost their market presence.

The ability to select from diverse materials, innovative lens options, and unique design choices allows brands to tailor their eyewear products to meet specific consumer needs. Our commitment to high-quality craftsmanship and state-of-the-art customization processes ensures that every pair of glasses we produce is a reflection of our client’s vision and brand ethos.

We invite you to connect with us at Joysee Eyewear to learn more about our customized glasses manufacturing options. Whether you’re ready to start your customization journey or need further information, our dedicated team is here to assist you in creating eyewear that truly stands out. Let’s collaborate to elevate your brand in the eyewear industry and capture the attention of your target audience with bespoke designs tailored just for you.

Customization Options in Glasses Manufacturing

| Category | Options |

|---|---|

| Material Choices | 1. Metal Materials – Copper – Stainless Steel – Aluminum-Magnesium Alloy – Titanium Alloy 2. Injection Plastic – Polycarbonate – TR90 – Acrylic Plastics 3. Sheet Plastics – Acetate – Bio Acetate 4. Bamboo/Wood Materials – Bamboo – Wood |

| Lens Materials | – Optical Glass – Polycarbonate – Nylon – CR39 Resin – MR-8 |

| Lens Functions | – Polarized Lenses – Photochromic Lenses – Blue Light Protection Lenses – Sunglass Tinting |

| Lens Classification | – Single Vision – Bifocal – Progressive – Customized Lenses |

| Lens Tint Options | – Solid Color – Gradient Color – Dual Gradient – Revo Mirror Coating |

| Design Options | – Diverse Material Colors and Designs – Custom Logo and Placement – Design Formats and Proposals |

- Glasses Manufacturers—What to Look For in Your Partner

- 1. Innovative Customized Glasses Manufacturing Options

- 2. Glasses Manufacturers Quality Assurance: Standards, Testing

- 3. Benefits of Partnering with Chinese Glasses Manufacturers

- 4. Sustainable Eyewear Trends: Eco-Friendly Manufacturing Practices

- 5.Choosing Glasses Manufacturer for Your Brand

- 6. Glasses Manufacturing Process: How Eyewear is Made

- 7. Trends of Technology in Glasses Manufacturing

Allen Lin

Position: Owner

Company: Joysee Eyewear

Email: allen.lin@joysee-eyewear.com

WhatsApp: +8613456050627

Website: www.joysee-eyewear.com